title: SilverLeaf BioTrack Inventory Processing ms.service: dynamics365-business-central, SilverLeaf, Track & Trace ms.topic: article ms.search.keywords: dynamics, BC, Business Central, SilverLeaf, Track & Trace, Inventory Destructions, BioTrack ms.date: 06/13/25 ms.author: ajones

Inventory Processing

In Business Central, there is the concept of the Item Card. This master record holds all the details of a specific product in one place. BioTrack does not have a similar concept. Instead, when a new tag is posted in BioTrack all the information relating to it is sent with the tag every time. BioTrack relies on the Category and Sub Category to determine what types of transactions may be made against an item.

There are three main types of transactions against items in BioTrack:

- Lotting - this is generally done when plant material from cultivation is ready to be moved to processing

- Conversion - this is generally done when turning a product into a different product during a manufacturing process

- Sublotting - this is generally done when creating new tags from a single tag for the same inventory type. Typically, when a finished good item is QA tested and being broken out into smaller tags to be sold.

The following will need to be configured to do inventory processing in BioTrack:

- The Location should be Track & Trace enabled and mapped to a Track & Trace License on the License and Permits page

- Track & Trace Rooms should be configured and mapped to Location Rooms

- Temporary CBC Tags should be created for the Location

- Track & Trace Units of Measure should be downloaded and mapped to Business Central Units of Measure

- Track & Trace Product Categories and Subcategories should be downloaded and mapped to Business Central Items that are configured to be Track & Trace enabled

There are multiple ways to process inventory in the system. It can be done through: Released Product Orders, the Scan Worksheet, Product Conversion Orders, Product Conversions or Assembly Orders depending on system configurations.

How-to: Process an Inventory Conversion from the Product Conversion Order

Search for Product Conversion Orders and click the related link.

On the menu, choose the New option

On the Product Conversion Order's General FastTab, enter the following for the product to be output:

- Item No.

- Variant Code

- Location Code

- Bin Code

- Starting Tag Type

- Starting Tag No.

- Quantity per Output Tag

- No. of Output Lines

On the menu, choose the Create Output Lines Action. This will create the output tags on the Output Lines FastTab. Verify the lines have the correct information.

Note

The tags on the lines will be temporary tags. Once the tags are posted, BioTrack will generate the tag numbers to use and the temporary tags will be renamed to the tag number BioTrack provides.

On the Consumption Lines FastTab select the items with their tags to consume to produce the output inventory.

After selecting the items, enter the Quantity to consume on the consumption lines.

Note

The quantity to consume defaults to the quantity available on the tag. Be sure to double check the Quantity prior to posting so overconsumption isn't accidentally posted.

Once all of the information has been verified, choose the Post action on the menu to post the Product Conversion Order.

The Web Integration Log will show the call made to BioTrack and the Item Ledger Entries will show the conversion with the BioTrack Tag numbers provided from the integration.

How-to: Process sublots from the Scan Worksheet

Search for Scan Worksheet and click the related link.

Verify the batch you are in is for the appropriate license location. If it is not, change the batch.

Scan or enter the tag number into the Scan field.

Choose the Split menu action to open the Scan Split worksheet.

On the Scan Split worksheet, choose the Create/Reclass Package Lot(s) action and enter the following

- Source Quantity to Use (Base)

- No. of Lots

- Quantity per Lot (Base)

- Starting Tag Type

- Starting Tag No.

Click OK and the tags will be generated in the Scan Split worksheet. Verify the quantities and click OK to sublot the tag.

Note

The tags on the lines will be temporary tags. Once the tags are posted, BioTrack will generate the tag numbers to use and the temporary tags will be renamed to the tag number BioTrack provides.

The Web Integration Log will show the call made to BioTrack and the Item Ledger Entries will show the sublots with the BioTrack Tag numbers provided from the integration.

How-to: Void a Lab Sample

When integrating with BioTrack, users will need to sublot source tags for testing. The Void a Lab Sample button will remove the inventory on this sublotted tag and add it back onto the source tag.

- First, navigate to the Sales Order line for the sample you want to void and remove the Item Tracking Lines.

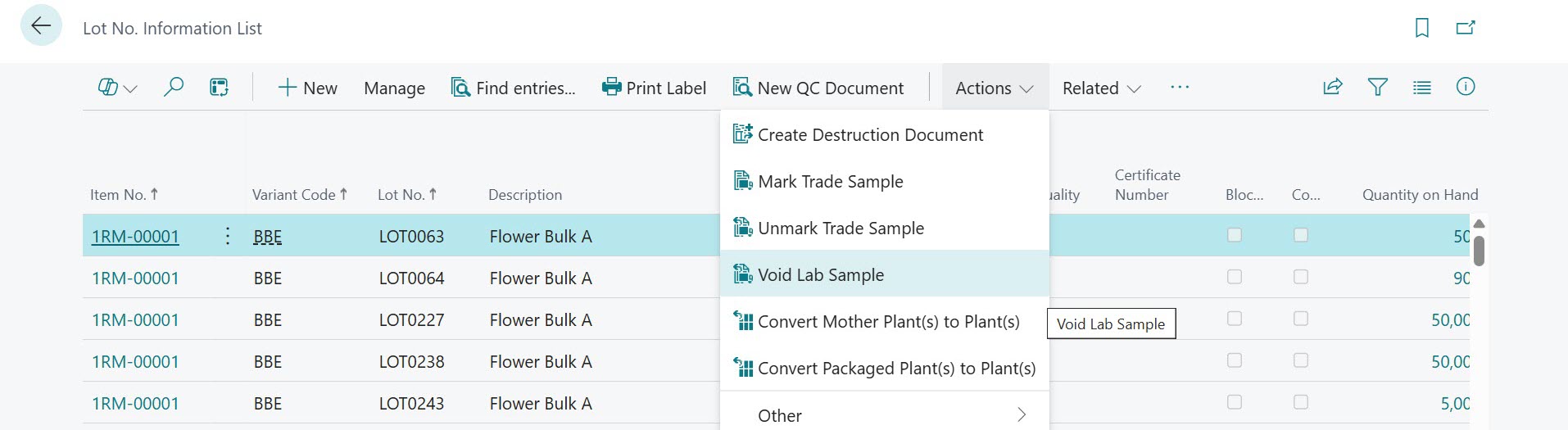

- Then navigate to the Lot No. Information Card for the test lot.

- In the top Ribbon click Actions and then select Void Lab Sample

- In the pop-up, confirm the tag and quantity, then click OK.

- The tag inventory will be removed and added back to the source tag.

How-to: Record Production Waste

BioTrack requires tag conversions for waste in the production process. SilverLeaf Track & Trace can do this when the tag provider is BioTrack and the Production Waste Item is set on the Routing or on the Production Order.

- When a Production Waste Item is specified, these additional fields will need to be filled in to output the waste:

Note

These fields may need to be added to the page through personalization

- Production Waste Quantity

- Waste Tag Type

- Waste Tag No.

- Destruction Option

- After the posting process is initiated, the waste tag will be returned to BC from BioTrack and waste output on its own Production Line.

- To finish the waste process, post the Destruction Document for the waste.